No products

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

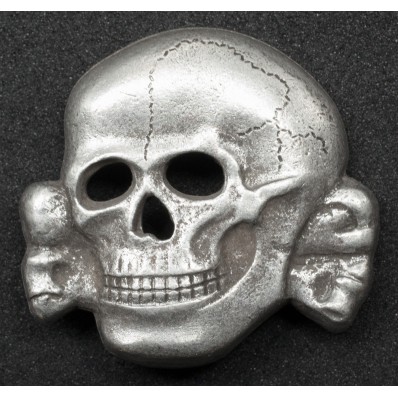

Waffen-SS Totenkopf Skull Badge For Visor Hat (Schirmmütze)

New

Visor-cap Totenkopf badge used by Waffen-SS units. Produced in Cupal, aluminum, and later zinc alloys; often silver-plated. Identifiable maker codes include RZM marks such as M1/52 (Deschler) and 499/41 (Zimmermann). Mounted by prongs/pins to the front cap band.

- Satisfied or refunded: we guarantee 100% secure protection on your purchases

- Free return: return your order free of charge within 30 days from receipt

- Secure payments: pay securely online with PayPal or credit cards

More info

1. Historical context and function

The Totenkopf motif predates National Socialism and has earlier European martial and heraldic precedents; within the structures of 20th-century German forces it was appropriated in various contexts and became characteristic of certain SS units. On the peaked service cap (Schirmmütze / visor cap) the Totenkopf served as an emblem of unit identity and presence on parade and formal uniforms, not as an award. Institutional and museum records document its presence across guard, administrative and combat formations.

2. Materials and manufacturing methods

Early high-quality examples were typically executed in Cupal (a copper-aluminium composite) or aluminium with a silver finish, producing a durable, lustrous surface. Wartime economy measures brought increased use of zinc alloys with thinner electroplated finishes. Manufacturing steps included blanking/pressing from sheet, hand finishing and final plating; attachment provisions were formed during stamping or soldered subsequently. Differences in substrate metal, plating thickness and finishing detail are primary markers for typological dating and attribution.

3. Maker marks and RZM coding

From the period of regulated supply, makers’ marks and Reichszeugmeisterei (RZM) codes were stamped on many insignia backs; typical identifiers for visor Totenkopf badges recorded in literature and sale catalogues include M1/52 and 499/41, which correspond to documented manufacturers (Deschler & Sohn; Fritz Zimmermann). The presence, style and placement of these marks are central to provenance research and marketplace attributions.

4. Typologies and diagnostic details

Diagnostic features used to differentiate types include skull-shape profile, nasal aperture geometry, teeth depiction, style of crossbones, prong system (flat tabs vs U-clamps vs round pins), surface texture and edge finishing. Early manufacture shows crisper modeling and heavier plating; later wartime examples are simplifications with thinner metal sections and cruder detail. Comparative typologies are catalogued in specialist references and auction archives.

5. Authentication practice

Authentication combines visual typology, maker-mark verification, metallurgical checks (non-destructive XRF to determine alloy composition), assessment of patina consistent with expected corrosion processes, and comparison against well-documented reference examples held by museums and private collections. Repairs, modern reproductions and counterfeit marks are common on the collecting market; methodical documentation is necessary for reliable attribution.

6. Provenance and legal considerations

Museum records include Totenkopf examples within historical collections; commercial markets and auction houses also trade these artefacts, sempre subject to deontological and legale constraints. In some jurisdictions, display and trade of items bearing extremist insignia are regulated and limited to contexts of study, documentation or heritage preservation; professionals in the field follow legislated limits and museum guidelines.

7. Conservation notes

Conservation emphasizes preventive measures: control di umidità, manipolazione limitata, stabilizzazione della placcatura e documentazione fotografica. Non si raccomandano rimodellamenti o re-placcature integrali che cancellerebbero informazioni storiche cruciali.

Data sheet

| Width | 28.10 mm |

| Lenght | 29.60 mm |

| Thickness | 1.30 mm |

| Weight | 5.8 gr |

| Material | Zamak, Brass |

Cap and Helmet Badges

- Germany

- Medals, Orders and Decorations

- Badges and Pins

- ID Tags

- Arm Shields

- Visor Caps and Hats

- Cap and Helmet Badges

- Collar Tabs Cyphers

- Collar Tabs, Shoulder Boards and Epaulettes

- Arm Bands

- Division Cuff Titles

- Buckles And Belts

- Buttons For Uniforms

- Stamps

- Gorgets

- Rings

- SS Honour Ring in 925 Silver - Collector's Set

- Poletops

- Flags

- Daggers and Knives (Ornamental)

- Field Marshal Batons

- Ammo Pouches, Bandoliers and Bags

- Service Watches

- Presentation Cases

- Documents and Award Letters

- Busts, Eagles, Lighters and Miscellaneous

- Croatian and Ustasha Militaria

- Denazified Articles

- Commemorative Necklaces

- Spare Parts, Small Parts and Accessories

- Italy

- Medals and Decorations

- Brevets And Badges

- Battle Shields and Tags

- Gorgets

- Visor Caps and Hats

- Cap and Helmet Badges

- Friezes for Collar Tabs

- Collar Tabs, Shoulder Boards and Epaulettes

- Buckles

- Buttons For Uniforms

- Rings

- Poletops

- Italian Resistance

- Keyrings

- Wallshields

- Daggers and Knives

- Flags

- Busts and Eagles

- Souvenirs

- Commemorative Necklaces

- Imperial Germany

- Soviet Union

- Other Countries